- Published on

How Code Controls Machines

- Author

- Name

- Robert Kirby

- Title

- Lead Full Stack Developer at Y-Squared

Blog Post 8

How Code Controls Machines

TABLE OF CONTENT

1 INTRODUCTION

2 CODE EXECUTION

3 HARDWARE INTERFACE

4 ACTUATORS

5 APPLICATIONS

6 SAFETY AND MAINTENANCE

7 LINKS

_________________________

Image Source: https://unsplash.com/photos/jHZ70nRk7Ns

1 INTRODUCTION:

In today's world, machines are becoming increasingly sophisticated and are playing a larger role in our daily lives. From factory automation to space exploration, machines are being used to perform a wide variety of tasks. However, the key to making these machines work is the code that runs on them. Code, in the form of software, is what gives machines the ability to perform specific tasks, and it is what makes machines so versatile and powerful.

In this article, we will take a closer look at how code controls machines, from the execution of the code to the physical movement of the machinery. We will explore the different types of actuators that are used to convert electronic signals into mechanical motion, and we will see how code is used in different applications such as industrial automation, robotics, and aerospace. Additionally, we will discuss the importance of safety features and error handling mechanisms in code that controls machines, as well as the maintenance required to ensure proper and safe operation of the machinery.

_________________________

2 CODE EXECUTION:

The first step in understanding how code controls machines is to understand how code is executed. Code is typically written in a high-level programming language such as C++, Python, or Java and then translated into machine code, a set of instructions that the computer's processor can understand and execute. The processor, also known as the central processing unit (CPU), retrieves the instructions from memory and decodes them to understand what operation to perform.

The process of executing code begins when the CPU retrieves an instruction from memory and decodes it. The instruction is then executed by performing operations on the hardware. For example, an instruction to read data from a storage device would be sent to the storage controller, which would then retrieve the data and send it back to the CPU for processing.

Each instruction is executed one at a time in a sequential manner and the execution of instructions is known as instruction cycle. The CPU also uses control signals, address bus and data bus to communicate with other devices and control their operations.

It is important to note that the speed of code execution depends on the clock speed of the CPU and the number of instructions that can be executed per clock cycle. This is why faster processors are able to execute code faster.

In summary, the CPU acts as the brain of the computer, interpreting and executing instructions, and controlling the various hardware components to perform the tasks specified by the code.

_________________________

Image Source: https://unsplash.com/photos/JMwCe3w7qKk

3 HARDWARE INTERFACE:

Once the code is executed by the processor, it must then interact with the various hardware components in the machine to perform its tasks. These components include memory, storage devices, input/output devices, and peripherals such as displays and keyboards.

One way that code interacts with hardware is through memory. The code is stored in memory and the processor retrieves it from there to execute it. Additionally, memory is also used to temporarily store data that the code is working with. The code also interacts with storage devices such as hard drives and solid-state drives to read and write data.

Another way code interacts with hardware is through input/output (I/O) devices. These devices allow the code to receive input from the user or from sensors, and to provide output in the form of visual or audio feedback. For example, a code that controls a robotic arm would receive input from sensors on the arm, such as encoders, and provide output in the form of movement of the arm.

To communicate with these devices, the CPU uses a system bus or high-speed interconnects. The system bus is a set of communication lines that connect the CPU to other devices such as memory, storage, and I/O devices. The CPU also uses control signals, address bus and data bus to communicate with these devices and control their operations.

It's important to note that the code must be written specifically for the hardware that it will be interacting with. Additionally, the code must also include the necessary drivers to communicate with the specific hardware components.

_________________________

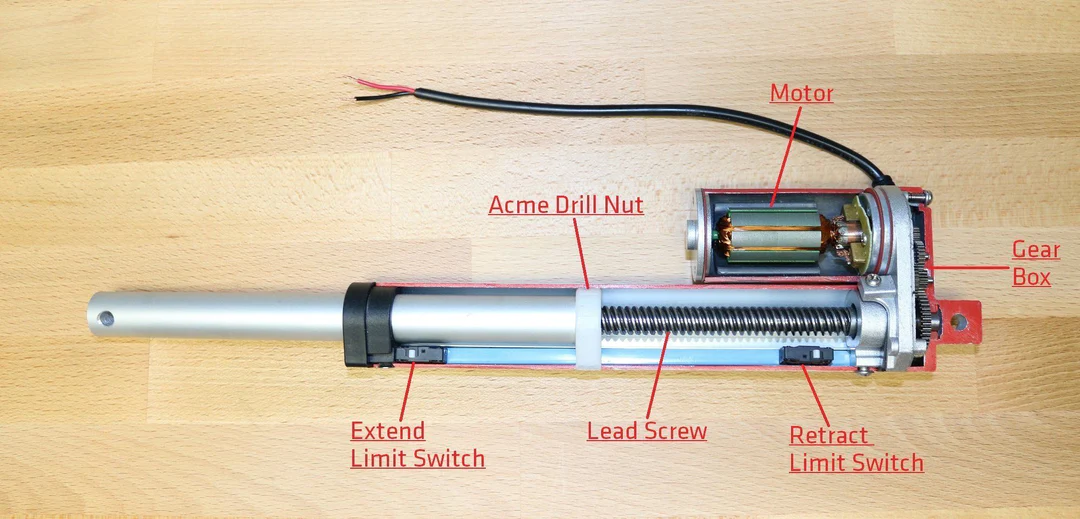

Image shows Electric Linear Actuator

Image source: https://www.progressiveautomations.com/blogs/products/inside-an-electric-linear-actuator

4 ACTUATORS:

While code controls the logic and flow of the machine operations, actuators are the devices that physically perform the actions. Actuators are devices that convert electrical signals into mechanical motion. They are used in a wide variety of applications, including robotics, industrial automation and mechatronics systems. Actuators can be classified into different types based on the type of motion they produce, such as linear, rotary, or oscillating motion.

Some common types of actuators include:

- Electric motors, which convert electrical energy into rotary motion. These can be further classified into different types such as DC motors, stepper motors, and servo motors.

- Pneumatic and hydraulic actuators, which use pressurized fluids (air or oil) to generate linear or rotary motion.

- Solenoids, which convert electrical energy into linear motion.

- Piezoelectric actuators, which use the piezoelectric effect to generate very small linear or rotary motion.

- Thermal actuators, which use the expansion and contraction of a material due to temperature changes to produce motion.

The code sends instructions to the actuators, which then physically move the machine's parts. For example, in the case of a factory automated arm, the code would specify the movement of the arm, such as the position and speed of the movement. This information would be sent to the actuators, which may be servo motors or hydraulic pumps, that would then physically move the arm to the specified position. In the case of a rocket, the code would specify the actions of various systems such as the thrust of the engines, the angle of the fins, and the deployment of the parachute. These actions would be controlled by actuators such as solenoids and motor-driven valves that physically control the flow of fuel and the movement of mechanical parts.

It is important to note that the choice of actuator depends on the specific application, and that the code also must be written to interface with the specific actuators being used. Additionally, actuators are subject to wear and tear and regular maintenance is required to ensure proper and safe operation of the machinery.

_________________________

Image Source: https://unsplash.com/photos/MECKPoKJYjM

5 APPLICATIONS:

Code controls machines in a wide variety of applications, from factory automation to space exploration.

Some common examples of applications where code controls machines include:

- Industrial Automation: Code is used to control various machines in factories such as assembly lines, conveyor belts, and robotic arms. These machines are used to automate repetitive tasks and improve efficiency. Code is also used to monitor and control the processes in the factory, such as temperature, pressure, and flow.

- Robotics: Code is used to control the movement and actions of robots. Robotics code can be used for tasks such as navigation, object recognition, and manipulation. Robotics applications include medical robots, industrial robots, and autonomous vehicles.

- Aerospace: Code is used to control various systems in aerospace, such as propulsion systems, navigation systems, and guidance systems. Code is also used to monitor and control the flight of aircraft and spacecraft.

- Medical devices: Code is used to control medical devices such as imaging machines, surgical robots, and diagnostic equipment. Code is also used to process and analyze the data collected by these devices.

- Building Automation: Code is used to control various systems in buildings such as lighting, heating, ventilation, and air conditioning. Code is also used to monitor and control energy consumption, security, and safety.

In these applications, the code is written to perform specific tasks and to interface with the specific actuators being used. Additionally, the code must also include safety features and error handling mechanisms to ensure proper and safe operation of the machinery.

_________________________

Image source:https://unsplash.com/photos/uj3hvdfQujI

6 SAFETY AND MAINTENANCE:

Code that controls machines must include safety features and error handling mechanisms to ensure proper and safe operation of the machinery. Safety features can include limits on the movement of machinery, shutdown procedures in case of errors, and emergency stop buttons. Error handling mechanisms can include error codes and logs, which can be used to diagnose and fix problems.

Proper maintenance is also essential to ensure the safe and proper operation of the machinery. Actuators, for example, are subject to wear and tear and need to be regularly maintained to ensure that they continue to function properly. This can include regular inspections, cleaning, and replacement of parts as needed.

Proper maintenance also includes keeping the code and the software updated. As technology advances, new features and security patches are released, and it's important

to keep the software up-to-date to ensure that the machinery continues to function properly and securely. This can include updating the operating system, libraries and frameworks, and installing security patches.

It's also important to note that safety regulations and standards must be followed when designing and operating machinery. This includes following guidelines from organizations such as OSHA and ISO for safe design, operation, and maintenance of machinery.

In summary, safety and maintenance are crucial aspects of code that controls machines. Safety features and error handling mechanisms must be included to ensure proper and safe operation of the machinery. Regular maintenance, including inspections, cleaning, and replacement of parts, must also be performed to ensure proper operation. Additionally, software must be kept up-to-date and safety regulations and standards must be followed to ensure the safety of the machinery and the people who operate it.

_________________________

7 LINKS

Please contact us if you see any mistakes on this post, have any suggestions or business inquiries.

Please fill out the form on https://y-squared.com/contact or email us at team@y-squared.com.

The Author:This post was written by Robert from Y-Squared:

Click here to follow me on Github @Rob1818

Blog Site:

Medium:(Follow me on medium)

https://medium.com/@Robert-Y-Squared/how-code-controls-machines-2785fb6443c1

https://medium.com/@Robert-Y-Squared

Business Site:(Fill in the form if you have any business inquires)